Technical

/

Technical Data

1. Grounding

An earthing system (IEC) or grounding system (IEEE) connects an electrical power system with the earth’s surface, for both safety and functional purposes. Earthing systems also affect electromagnetic compatibility and are required for lightning protection systems.

Earthing systems fall under two categories: system grounding and equipment grounding.

System grounding is the deliberate connection to earth of a phase or neutral conductor to control voltage stress and voltage hazards (touch or step voltages) to within safe limits.

Equipment grounding is to electrically interconnect or to ‘bond’ the non-current carrying conductive parts of equipment together and to the earth.

Earthing systems must be carefully designed. There are many earthing and grounding system related standards the designer needs to consider.

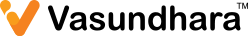

Grounding refers to connecting a system supply, such as a generator neutral or a transformer, directly to the ground without any intervening impedances. This is a particularly good way to avoid excessive fault currents. The effectiveness of a solidly grounded system can be determined by comparing the ground-fault current to the three-phase fault current. The higher the ground-fault current compared to the three-phase fault current, the greater the degree of grounding in the system.

2. Lightning

Formation of Lightning

FIRST PHASE OF DISCHARGE

Lightning discharge is observed in the form of a light from the cloud to the ground. However, it goes out after it has covered part of the path between the cloud and the ground. After a period of time that can be measured in microseconds, a second flux follows the path of the first flux and thus a pre-discharge occurs. This type of flux is also called “pilot discharge”. Because the cloud base charge is negative, the pilot discharges are extinguished before they reach ground. The tip of the pilot discharges is very close to the ground. However, the jumps are 30-40 meters long and independent of the soil surface.

SECOND PHASE OF DISCHARGE

As a result of the increase in the electric field intensity on the soil surface with the movement of the pilot flux, a discharge that we can call the “Ground discharge” in the opposite direction (from the ground up) and with a positive (+) value arises. This discharge continues until the pilot, which has begun to extinguish, reaches the discharge and its path to the charged cloud. (This is the reason why it is wondered whether the lightning discharge is air-to-ground or ground-to-air) At this stage, the second phase is now formed. The activation phase of the active lightning rod is in the second phase. By increasing the intensified electric field, they ensure that the main discharge is grounded on themselves, not from anywhere, in the next phase.

THIRD PHASE OF DISCHARGE

Now the ground discharge has reached the charged cloud. Other discharges from the cloud, which could not discharge its charge in the previous phases, now follow the ionized channel formed by this ground discharge and flow to the ground through this channel one after the other. Therefore, they flow to the ground over the active lightning rod, which has increased the electric field intensity in the second phase. This is why active lightning rods are called “Early Flow Alert (E.S.E)”.

3. Passive Rods- Franklin rod

The simplest protection

Passive rods or Franklin rods are the most common and simple lightning rods (SR). These can be used as the only sensor element or be part of passive protection systems, complementing the protection in conductive meshes (Faraday cages).

Franklin rods do not perform any special action during the electrical storm process, the protection of these points is based on the position of the rods, the morphology, material, and the physical reaction that takes place in the electrostatic field.

FRANKLIN BAR (Static Catch Tip)

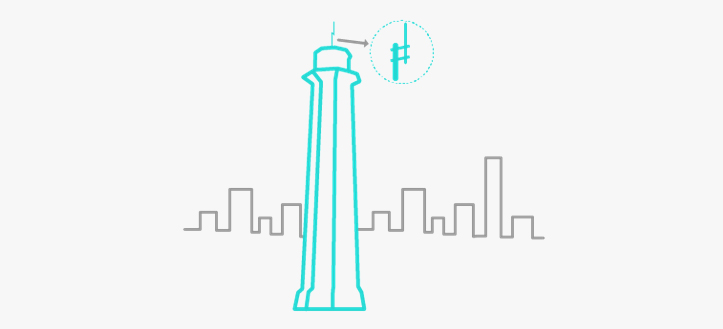

It is the most classical method of lightning protection. The conductor rod, which is mounted on a high place, creates a 45 degree protection area towards the ground, with the apex. This cone extending down from its apex is called the “Franklin cone”. The protective field radius is equal to the height of the catch tip from the ground (h).

It does not have lightning protection feature when used in buildings in large areas, and it has an effective protection area in structures with narrow base but high height such as minarets, chimneys, towers and lighthouses. It is a lightning protection method that is still used in thin and long structures, which are still mentioned today.

FARADAY CAGE

This system, named after its inventor, Michael Faraday, is used to protect buildings or buildings spread over a wide area from lightning. It is an advanced version of the Franklin bar system with an overall perspective. It is based on the principle of extending the conductors in width and length according to the desired protection efficiency on the roof of the building, mounting a catch point at each intersection, and grounding the conductors by extending them to the ground throughout the building. Lowering conductors are connected to the grounding conductor, which is formed at the ground level of the building and surrounds the building. Although the system is still in use, it is not widely used due to its inability to protect the exterior of the building from lightning and its high cost.

4. Active Rods- ESE Lightning Arrestor

Working Principle of Active Lightning Rod

Active lightning rods are also known as lightning rods working with the early flow warning principle. They are also defined as E.S.E active lightning rod by taking the initials of the Early Streamer Emission English word group. The working principle of active lightning rods is based on increasing the electric field intensity according to the current air loads. Thus, it provides protection against negative or positive lightning types. This method, which has been developed recently in lightning protection, is rapidly becoming widespread. The working principle of these lightning rods is to catch the lightning before it merges with the earth and transfer the discharge to the ground safely. For this reason, the catching speed (Δt) becomes important in active lightning rods. Thanks to the electric field it creates in the air, the active lightning rods, which prepare a conductive path to the lightning and give it to the ground, do not cause unnecessary discharges because they do not ionize the air. Active lightning rods (ESE) get their energy from the change of electrostatic and electromagnetic field density in the air.

Features of Active Lightning Rods

The most important features of active lightning rods are that they provide effective protection from lightning in the circular area where they are installed. Therefore, with a suitable project, both economical and effective lightning protection is made with active lightning rods. In active lightning rod systems, a single point landing from the lightning rod facility to the ground is sufficient. However, in very high buildings, it is necessary to lay the conductor on the outer surface of the building horizontally every 20 m, and this system is called “belting”. The grounding of the active lightning rod system, just like the faraday cage, must be extremely good. Usage areas of active lightning rods: Active lightning rods, which can be applied to all buildings, open areas easily and in various ways, are suitable for life such as schools, hospitals, factory buildings, base stations, fuel filling and sales stations, airports, stadiums, apartments, summer sites, mosques, churches and synagogues. It is used in all buildings and facilities in our area.

5. Why install an ESE?

Nothing can stop the formation of lightning during a storm, but installing a lightning rod with an Advance Systems KALRE device ensures an optimal level of protection, offering maximum safety to people, animals, and electrical installations. ESE lightning rod having triggering device to create an upward-leader.

The ALR, STRONG lightning rods are the perfect solution to protect against lightning, being capable, through correct installation, of conducting all the lightning energy to the ground safely. In addition, all KALRE lightning rods have a 20 years warranty against any manufacturing defect. See terms and conditions

Protect residential buildings, private homes, or industries of any kind with our protection systems. Rate your safety.

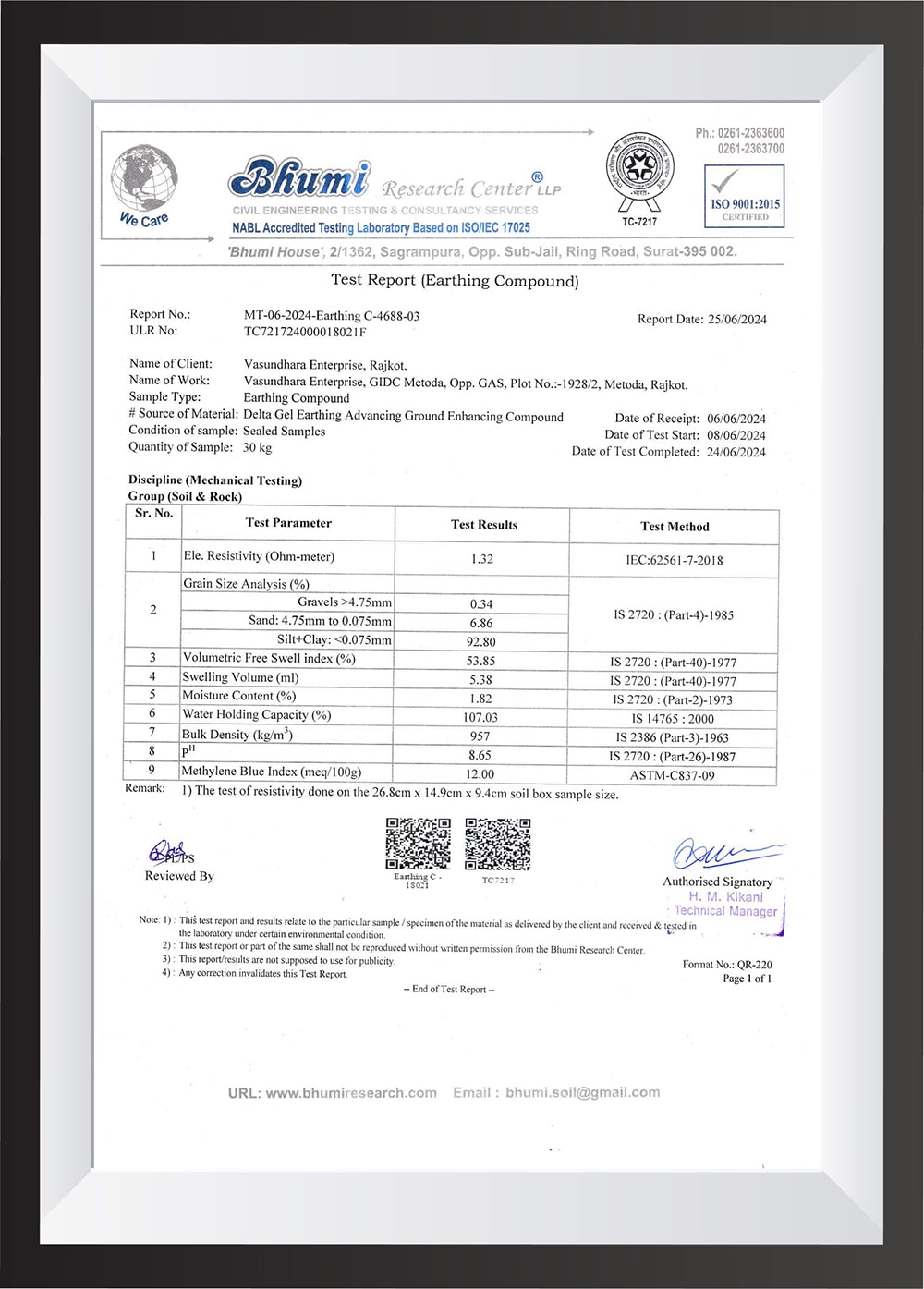

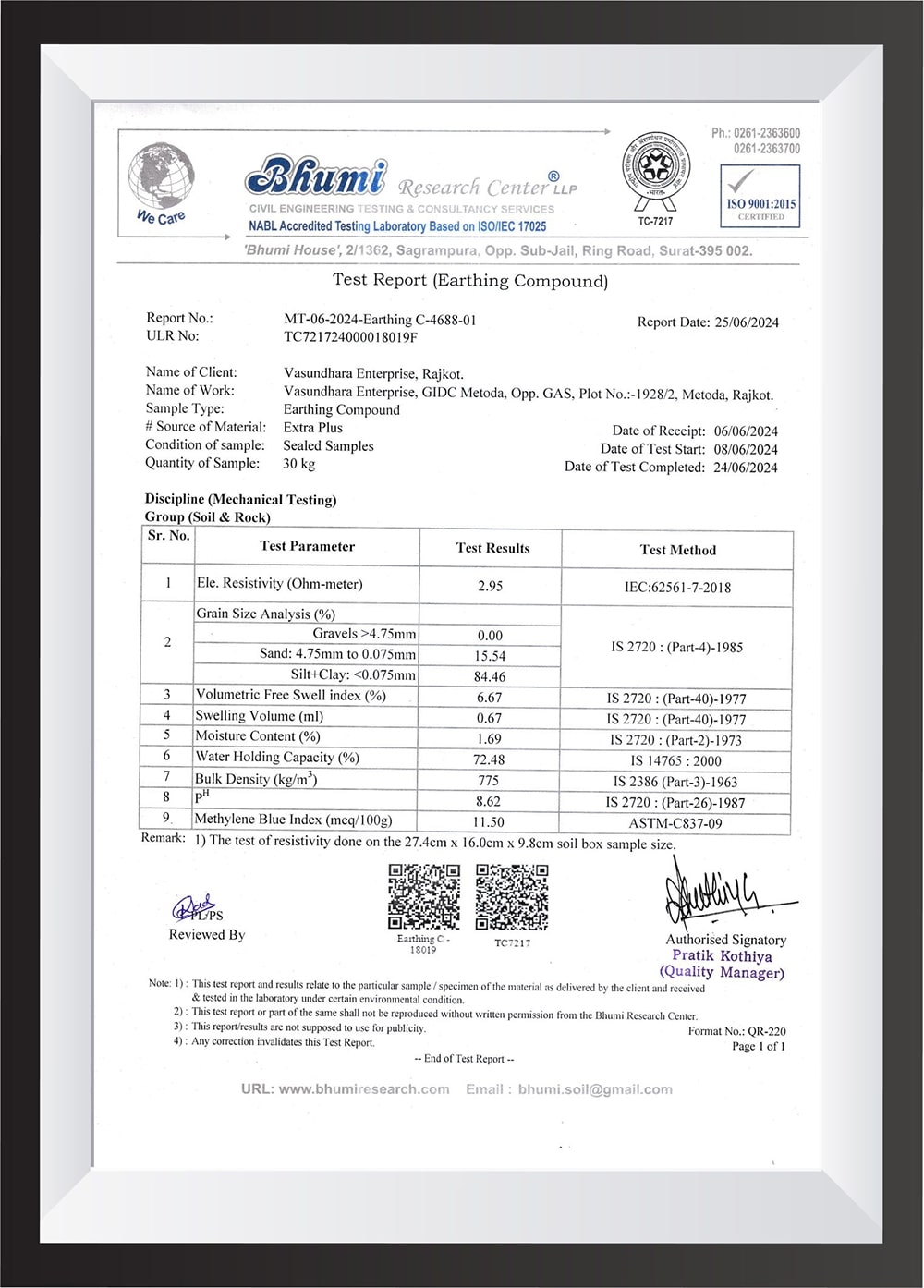

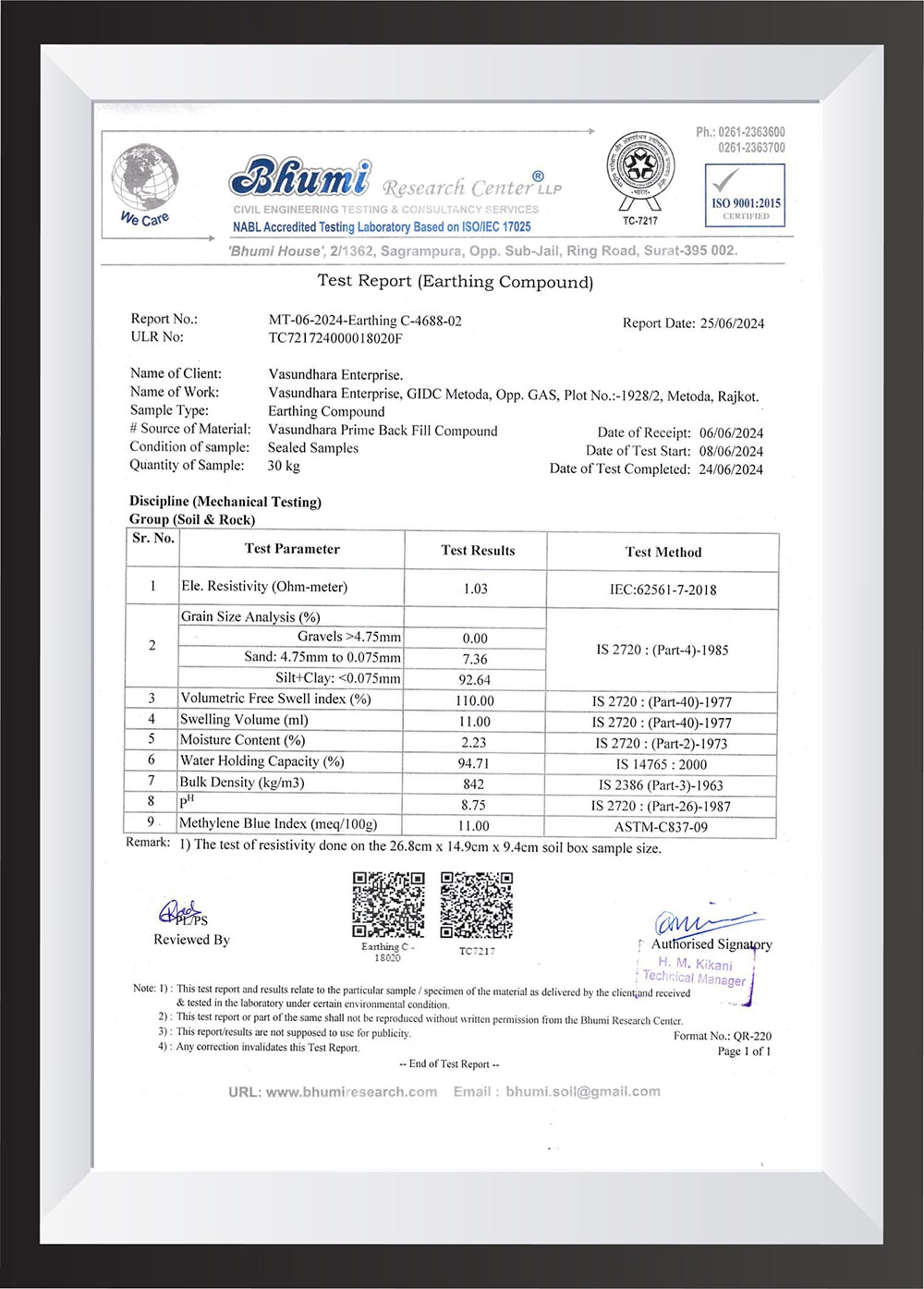

Certificate's

You will find yourself working in a true partnership that results in an incredible

experience, and an end product that is the best.

Contact Info

Office : Opp. Tagore School, B/h. Copper Heights, Off. Sadhu Vaswani Road, Rajkot - 360005 (GUJARAT) INDIA.

Factory : C/1928/2-3, J Road, Metoda GIDC, Gate No. 2, Metoda, Rajkot - 360007 (GUJARAT) INDIA.

Customer Care No.: 90330 04276